Your Cart is Empty

Luggage

Apparel

Events

The Mosko Blog

Honduras, Take 2

January 09, 2014

Honduras, Take 2

January 9, 2014

Last winter I was riding through a remote corner of NE Honduras called La Moskitia (the “Mosquito Coast”). I went over the handlebars, broke a leg, got picked up by some soldiers, and flew to Miami for surgery. Here’s a quick recap:

I was on the side of the road for a few hours:

These soldiers came along and took me back to their base:

Due to bad weather, I camped on the base for a few nights until I could get a ride out:

I had to fly back to Miami to deal with the leg:

The bike suffered cosmetic damage but it still runs. It has been parked on a Honduran military base for most of the year:

(full story is here: http://advrider.com/forums/showthread.php?t=871303)

When I got home from the hospital and was hobbling around on crutches, Andrew and I hatched a plan to start making moto bags. That’s how this Mosko project got started. Now, a year later, I’m headed back to Moskitia to retrieve the bike and I’m taking our prototypes along for testing. The plan is to ride through Honduras, Nicaragua, Costa Rica, and Panama, and then ship the bike home from Panama City. I fly out on January 20th. We just decided this two days ago so there’s not much time to get ready. It’ll be a quick trip — a few weeks at the most — but enough to give the bags a good thrashing.

We took some time off for the holidays. Here’s a quick update:

Mounting Wedge

Hein finished milling the revised wedge and frame. This is the version I’m taking to Honduras.

The tolerances are much tighter than before, resulting in zero “wiggle” on the bike.

We added a “bump” on the beveled edge so the rack has this nice satisfying “thunk” when it clicks into position. It really feels solid:

Mounting Wedge Latch

We continue testing different latch mechanisms. We have two favorites, one is like a rubber jeep hood latch and the other is a stainless steel rotary draw latch.

I’m still not sure which I’m taking to Honduras. Maybe both. I was concerned about the draw latch in mud and dirt, but we tested it and it held up well. The rotary motion pushes mud out of the way as it turns, and the latch worked fine no matter how much crap we packed in there.

Molle Hydration Attachment

We spent some time with Chip this week developing our molle hydration concept and starting on a prototype.

We started with a sketch:

Took measurements of the MSR Dromedary and the 2l bladder we’re designing for.

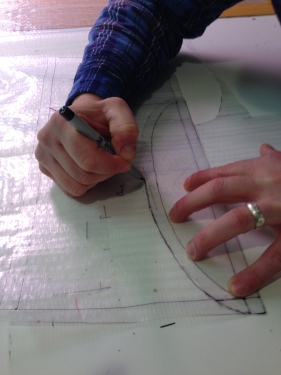

Sketched out some patterns on clear plastic:

Sewed the plastic together into a kind of sample bag:

Made some markings of where we want to add openings, nozzle sleeves, etc.

And then disassembled the plastic bag by cutting the seams. We took those pieces and used them as patterns for cutting actual fabric.

While at Chips we also spent a few hours cutting fabric for another pannier prototype — this time a “right” to go along with the “left” we made before — so I’ll have a complete set to take to Honduras for testing. Man it takes SO LONG to make a pannier. It’s crazy how complex it is now compared to a few months ago. On our first round prototypes we could practically cut and sew a pannier in a single afternoon. Now it’s a multi-day project.

Anyway, we left all the cut parts with Chip to work on through the weekend. By Monday, we should have a full set of panniers with liners, a duffle with liner, and hydration/bottle holder molle attachments. At least we’d better, because I need to start packing.

There’s been a lot of progress on the rackless bag and the apparel, more on that next week.

Happy New Year!!

Warranty and Crash Replacement

We never cut corners during development or manufacturing, so we stand behind our products. If one fails due to a problem with materials or workmanship, we’ll make it right.

Your are successfully subscribed for email notifications.

Notify me when available

We will send you a notification as soon as this product is available again.

Your email is required

We don't share your email with anybody

x