Your Cart is Empty

Luggage

Apparel

Events

The Mosko Blog

It’s All Happening

July 16, 2014

It’s All Happening

July 16, 2014

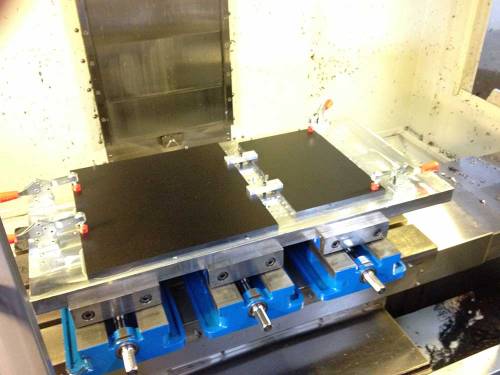

Machining of the pucks and mounts has begun in Portland, with various other bits and pieces making their way to the Gorge from all over the world. Yesterday we got a box of 595 latch keepers, tomorrow we’re picking up laser-cut logos for the wedge. Here’s some pics of pucks and frames/wedges in production.

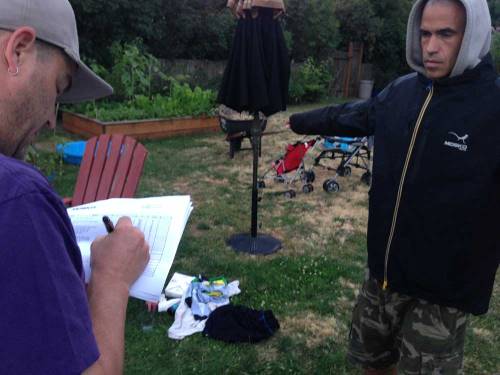

On the bags themselves, we made some last-minute changes to increase the strength of the roll top fabric, and reinforce some specific high-wear spots. We took our existing prototypes up to Chip and he got them all fixed them up.

There’s an additional wear spot on the back of the bag, where the fabric has been pushing up against the wedge-mounting screws. We fixed this by machining the channels for the mounting screws a bit deeper in the wedge so they don’t make contact with the fabric.

Now we’re just waiting on the final word from the factory so Andrew can hop on a flight and be there in person for production. Steve from the factory was in Portland again last week, and he came up to Hood River to discuss the production schedule. Steve grew up riding dirt bikes in Georgia but hasn’t been on a bike in years. He took Andrew’s KLR out for a spin.

Apparel

There’s nothing quite like having a physical prototype in hand to kick off the creative process. First we met with Galen in Portland for a high level review.

Man these pants would fit a giant. I’m 6’3″ and they’re about 5″ too long.

We followed up with a detailed fitting in Hood River. There are so many different measurements for every single garment, and all the pattern pieces interact with each other, meaning that a change in one pattern requires a change in all the others.

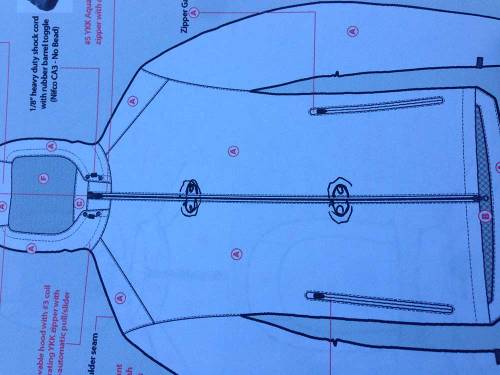

The liner jacket has a hood, which can be worn underneath a helmet in a serious downpour keeping water/air off the back/neck. In order to make the hood “helmet compatible” we’re making it slimmer and shorter than normal, so it doesn’t push down over the rider’s eyes (the white area below is being trimmed off).

We’re testing a system to attach the inner liner to the outer jacket when they’re being worn together. The liner can be used as a standalone jacket as well, for wearing around camp etc. But when they’re worn together, we want them to come on/off as one piece instead of two. So we’re adding some low-profile cord loops on the liner.

The cord loops wil correspond with small hooks on the outer jacket.

The samples were made from a fabric that is similar to but not exactly what we wanted. Our original fabric has more kevlar and is a bit heavier. But it wasn’t available in small quantities for sample making, so we have to use our imagination. Sample fabric is on the left, real fabric on the right.

The jersey fits pretty well. I’m wearing a pressure suit in this pic. It’s a little tight, so we’ll open it up a bit.

I’m leaving for a 4,000 mile trip on friday. I went out for a shakedown run last week wearing just an arcteryx shell, which is what I normally ride with offroad. Without a hydration pack to hold it down, the jacket was totally unmanageable at speed. It rode up on my belly and was non-stop flapping in the wind. Very annoying. No doubt this is one reason so many moto jackets are covered in pockets; the extra weight and stiffness of all that extra fabric helps hold the material place. However it also makes the jacket heavy, bulky, and hot. In our design, we’re going to add cinch straps on the sleeves and sides, which together with the draw string at the bottom should result in a highly configurable fit. The rider can adjust the width of the jacket based on how many layers are being worn underneath on that particular day (i.e. pressure suit, heated vest, insulated layer, rain liner, etc), and the jacket won’t flap or ride up when layers are removed. We want this jacket to work in huge variety of different riding conditions, whether cold/hot or wet/dry.

Reckless

We’re getting lots of questions about the Reckless: when will it be available, how much will it cost, what’s the volume etc. We’ve had so much going on with production of the Backcountry’s and Scouts that the Reckless development had slowed. Over the last few weeks we’ve been cranking on it again whenever we get some time. There are a ton of cool changes coming on this bag. Andrew will be developing this with the factory’s R&D team when he’s over in Vietnam.

We switched the direction of the beavertails, so now the rear beavertail overlaps the front. Originally we had it the other way, because it seemed more intuitive for aerodynamics, but the molle accessories kept bumping into our back while riding. The beavertail flip was suggested on advrider and we like it. The beavertail cinches down tightly, so air flows over it just fine, and it’s positioned behind the rider anyway, and therefore somewhat less exposed to wind.

The rear duffle will be a lot smaller than the version I took to Moab, so now the rider can fit a tent. sleeping bag, extra dry bag, thermarest, or other camping gear under the beavertail along with the duffle if needed.

We moved the side compression straps to a new connection point underneath the duffle, which makes it easier to get in/out of the rear beavertail, and results in a cleaner overall layout for the bag.

We changed side drybag closure, so the drybags now snap into the harness itself, as with the Backcountry/Scout panniers. This pulls the closure down and away from the top of the bag, greatly reducing the bulkiness of the closure compared to before.

We’re increasing the size of the internal mesh pocket on the front beavertail significantly (you can see the lines in the pic below), so it can fit a toothbrush and other stuff. Plus we’re adding a fold-out map pocket on the rear beavertail as well.

Rack Fitment & Mounts

With the BMW Owner’s rally coming up next week, we really need those fit kits for the curvy pannier racks. We spent an afternoon at BMW Motorcycles of Western Oregon in Tigard last week testing prototypes. Thank you Scott and Madelyn for letting us work on your show bikes!

The most difficult bike we’ve found so far is the new F800GS Adventure, because the rear gas tanks leave almost no clearance for an aftermarket bracket.

We finally gave in and bought one of these racks to set up in Andrew’s shed.

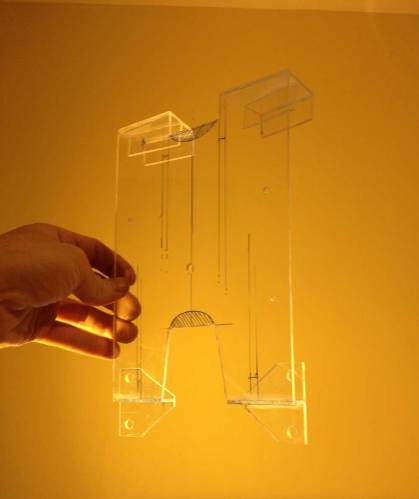

Now we have some bracket concepts we made in plexiglas which we’ll be prototyping in stainless with the laser cutter in Portland. Hoping we can have these ready for the BMW show in two weeks.

P-38 Shipments

We’re still getting lots of new mailing list signups through the website. We ran out of P-38’s after the NW Overland rally, but we just received a shipment of 1,000 more. If you’ve been waiting on a P-38, it’s coming.

SBA Loan

Mosko was approved for an SBA loan last week Not a done-deal yet, but we got an approval/commitment and now we’re working on the paperwork. That’s a relief, although now the house is on the line too.

BMW Owners Rally

The next sales stop for Mosko is the BMW Owner’s Rally in St Paul, Minnesota. I’m riding out on my R1150GSA. I don’t have a lot of time, but I’ll try to stick to the back roads wherever I can, and hopefully find some interesting dirt detours as well. I’m leaving Friday, so this week I’m working on bike prep, plus getting all our samples, brochures, and trade show stuff packed up and sent to St Paul.

If you’re at the rally please stop by our booth (#28) and say hi. And if you’re riding there, maybe I’ll see you on the road.

Warranty and Crash Replacement

We never cut corners during development or manufacturing, so we stand behind our products. If one fails due to a problem with materials or workmanship, we’ll make it right.

Your are successfully subscribed for email notifications.

Notify me when available

We will send you a notification as soon as this product is available again.

Your email is required

We don't share your email with anybody

x