Your Cart is Empty

Luggage

Apparel

Events

The Mosko Blog

May You Live in Interesting Times

August 11, 2021

August 11, 2021

Man has it ever been an interesting time.

If you visited our website recently looking for a product, you may have noticed that – aside from a brief period in late May when we got a small air freight shipment that lasted about a week – most items were continually out of stock until now. The water freight shipment we expected in July (which I mentioned in my last post) didn’t materialize until early August. Maybe you’ve read in the news about the supply chain issues that so many companies are experiencing. Here is the story of how those issues have recently manifested for us.

In normal (aka ‘uninteresting’) times, when we want to rush inventory from a factory, we send a small portion directly to Portland by air freight. The rest gets loaded in shipping containers, stacked on one of those big ocean-going container boats, and sent to the US by sea. Air freight is significantly faster than sea freight (10 days vs 30) but it’s also insanely expensive. It can easily cost 30-40% of the manufactured cost of the product. Typically we would send by air just enough inventory to cover the time difference between the two shipping methods, which is usually 30 days minus 10 days, or 20 days worth of inventory. Right when the air freight inventory runs out, the shipping container with bulk production should be landing at the warehouse, and we avoid a stockout. We might lose a little money on the air freight but we still do OK overall, because it represents only a small percentage of the total shipment.

On our most recent shipment, the one that’s in the warehouse now, instead of taking 30 days, the sea freight portion took 77 days. First, we couldn’t get space on a boat. Then one of our containers got transferred to a bigger boat. Then the containers got stuck offshore in the lineup to get unloaded in Seattle and Portland. Then one of the containers was flagged for customs inspection while the other got left in a ‘dark area’ of the port and couldn’t be moved. This is what we and many other companies have been experiencing with international shipping lately. It looks like it’s about to get worse not better.

For the last two months – despite having more inventory in production/transit than ever before, and with customer service calls/emails up 70% – we had nothing to ship. It was a weird feeling. Expenses carried on like normal, just without the revenue. Things got tight. Every morning started with the same question:

‘Beth, any news on the containers today?’

‘Nope.’

Finally, we got some apparel from an order we’d expected in May (3 months delayed). Then the bag containers arrived at the warehouse last week (on my birthday, best present ever). As soon as the inventory populated on the website we received about a month’s worth of orders in only 24 hours, and now we’re shipping all that inventory out. In the next few days we’ll run out of inventory again and the whole process will repeat. It’ll be 3-4 weeks before the next shipment arrives, depending on some factors I’ll describe below.

We mostly source from three Asian countries: Vietnam, China, and Bangladesh. China is doing ok compared to the other two (despite some significant delays caused by staffing issues), but Vietnam and Bangladesh are in the middle of their own COVID surges. They’re right where the US and EU were last year: cases are spiking, hardly anyone is vaccinated, and the governments have implemented widespread lockdowns and stay-at-home orders. Bangladesh is on full lockdown with factories closed, while Vietnam is on partial lockdown, with some factories closed but others (like ours) still operating under special restrictions.

We have the largest production order we’ve ever placed sitting in Vietnam right now, and it’s almost ready to ship. It was held up by two things: 1) we sent some washers (the ones connecting the Backcountry Panniers to their mounting frames) out for black oxide treatment in Ho Chi Minh City, then the HCMC lockdowns trapped the washers at the now-closed factory, and 2) we shipped the welded liner bags from our factory in China to our factory in Vietnam, but the shipment got trapped in the kerfuffle at the port and got delayed. The last news I heard as of a few days ago was that the liners had been freed but the washers were still trapped.

Next week we’re taking the entire order – including the unassembled panniers, frames, and washers (if we can get them) – and loading it onto a plane. A rough estimate is that it will be 29 tons of air freight, which is enough to fill about 1/5th of a 747 freighter. The cost at current shipping rates, which are more than double pre-pandemic levels, will be in the hundreds of thousands of dollars. It’s a big investment. We will need to temporarily raise prices to partially offset the added cost. It won’t be a huge increase, probably only around 5%. When that inventory lands, we will also need to assemble the panniers with US/EU labor, but at least we will have the inventory. The lockdown situation is changing so fast that if we don’t ship now, we might not get another chance for a while.

With all the delays, shutdowns, and port issues on both sides of the ocean, it seems like this chaos is likely to continue for a while. We’re taking it one shipment at a time. We’ll keep doing the best we can, bringing in whatever we can however we can. Another day in the life of a micro-multinational. Thanks for your patience.

Deluge Question

We are selling the last of our Deluge rain kits online right now at 50% off. They’re almost gone. It’s the first apparel item we’ve cleared out this way although I’m sure it won’t be the last. We’ve done some other discount sales but usually just on a prior season’s odds and ends. This was a new experience and we’re learning.

It would be awesome to get some feedback.

- Why did/didn’t you buy a Deluge?

- If you own one, what do you think of it?

- If we redesign or reinvent it, what would you like to see changed?

We can accumulate answers here on our advrider.com thread. Feedback much appreciated!! Don’t pull punches, give it to us straight. We have our own opinions and ideas but we really want to hear yours.

Almost everyone at Mosko has at least one Deluge, and we use them all the time for everything from trail riding, to desert trips, to wearing to work. It’s a great all-around 3-layer rain kit, although that wasn’t what we originally designed it for. The original concept was to pair the Deluge with your primary ADV kit for two layers of waterproofing in a multi-day downpour. Because on a long trip, when it rains hard enough for long enough and you’re riding straight into it, water eventually finds a way in. For the most part though, we ended up wearing the Deluge more often as a standalone rain kit than as an accessory to another kit, and it turned out to be really great for that.

Exhibit A: here’s a pic of Roel and Silke all bundled up in their Deluges (with Fernando in his Jackaloft) at our EU mobile outdoor headquarters last week.

Personally, I love the Deluge and I would hate to see it fade away. I feel like we need a stashable emergency rain layer in the line, and I definitely need one in my own riding kit. If we missed the mark the first time, there’s got to be something we could do better. Was it the price? the color? The features? The sizing?

What would it take to make the most kick-ass packable moto rain layer out there?

What would your ultimate emergency moto rain kit look like?

Here’s my take. I wish the Deluge packed even smaller. This feels a little sacrilegious to say, but maybe for this particular piece I don’t really care if it’s made from a $20/yard branded membrane. Maybe I don’t even care if it’s breathable. Given the short amount of time I’m wearing it, I might be happier with a $99 jacket made from a no-name $5-6/yard fabric that keeps the water and wind out and packs small enough to fit in my fist. I’m still using the Patagonia Houdini jacket in the pics below for mtn bike and moto and I love it. It’s just a windbreaker, not waterproof, but it’s so small that I can stuff it in my tank bag, plus it’s priced at exactly $99. If I tear a small hole I’ll patch it. If I tear a big hole I’ll replace it. Neither has happened yet.

I’d love to see a reinvented Deluge kit that’s similar to the Houdini, but waterproof. A front zip, velcro flap closure on the sleeves to keep out the wind, drawstring at the bottom, removable helmet-friendly hood, and killer price. Maybe with some hand pockets too, which the Houdini doesn’t have. That’s my vote.

New Products & Colors!!

Despite all the delays, it’s so awesome to have new stuff coming in!!

Basilisk Jacket & Pant:the new lichen colorway is so cool!

Workhorse Jersey: This is a really nice 3-season technical jersey designed for higher speed riding and light-duty abrasion protection (light-duty compared to a jacket, it’s heavy-duty compared to another jersey).

Jackaloft: New colorways, plus we loosened up the shoulders and armpits, and stiffened the collar a bit.

Graph Base Layer:This is our superlight graphene wicking base layer, that packs tiny and dries out super fast. This is a great crossover piece, I’ve been using mine for cycling, moto, hiking, etc.

Woodsman ITB/OTB: New colors, plus we increased the rise in response to the many requests.

Strata Base Layer: I am really excited about this one. I realize everyone already has one or several warm base layers that they like, probably something designed for a different sport (like skiing or snowmobiling), and that they tend to last forever. The Strata has some special features for moto travel that make it really unique. For example, the top turns into a cozy and presentable off-bike everyday travel hoodie (i.e pull it over a riding base layer and proudly walk into a bar for that Tinder date), and the bottoms zip-off down the sides so you can remove them without taking off your moto pants and boots (also handy on your Tinder date). Not having to strip on the side of the road to ditch a layer when temperatures rise? Priceless.

New Woodland Colorway

The Woodland colorway production keeps getting delayed. We’re currently expecting them sometime in late September. Man do they ever look cool though. We got final approval samples of the dyed ballistic items a few weeks ago and now we’re in love. They’re not even on the site yet but I already think we should reorder. If the response is as positive as we think, we’ll keep this colorway around for a few seasons.

Here’s what it looks like up against some different bike colors. I didn’t have a big ADV bike around at the time, but you know it’s gonna look cool on a GS or 1290. It’s refreshing to step out of the traditional moto gear colors for a change.

Wildcat Backpacks & Stargazer

We’re adding a colorway to the packs and Reckless bags for 22. We’re (temporarily?) calling it ‘Stargazer.’ It’s another sort of ‘out there’ colorway combining a matte outdoor blue with an intense hit of lime green.

We used some parts and pieces from old DaKine packs to mock it up.

I’ve been using the latest prototype of the smaller Wildcat pack. Between moving to a Tubliss system on my trail bike (no need to pack tubes) and storing tools in the new Gnat handlebar bag (no tools on the back), I’ve reduced what I’m carrying on my back a lot. It’s great. The smaller pack has just enough room for a pump, tow rope, water filter, SOL shelter, snacks, leatherman, and InReach.

New Jerseys Coming!

We have a ton of new jersey designs on the way. These are the ‘quick turn’ jerseys; that’s what we call them internally as a group, although they each have individual names based on the art and neckline. This is our basic, stretchy, summer-weight jersey with fully sublimated graphics that we change out frequently.

Here are a few pics.

We also have a sample of this super cool, super light, hugely open, hot weather mesh jersey. We love it. I love it. The only one small problem is that I took it out riding and it ripped on the first ride. And not in a crash either, I just looked down and there was a hole. I probably caught it on a passing branch. Maybe it was a fluke or maybe not, but I sure wish it hadn’t happened.

We should probably take the rip as a message and drop this style. It’s a bummer to buy something new and rip a hole so soon, even if you knew it was lightweight when you bought it, and even if the company will repair it for free. On the other hand, a super lightweight ventilated jersey like this is really nice on a hot day, and we all kind of intuitively understand that lighter things are generally more fragile. We were riding trails that were overgrown with bushes when this happened. In the desert the jersey might have lasted years. Even with my new wrist vent it still might. I could sew that hole up by hand with a needle and thread in 5 minutes.

Hmmm… what say you? Keep it or kill it?

The Gnat Handlebar Bag

The main challenge I see with the Gnat right now, is how to stop it from bouncing around. Strapping it to the handlebars is convenient but when you load it with something heavy – like tools – it wants to bounce, partly because the straps rotate on the handlebars and partly because the bag itself flexes, even when the rear wall is held still. It sags a little downward and then flops back up, which adds to the bounciness.

I transferred the full contents of my Pinner (which I use for trail riding) into the Gnat.

It’s kind of a shit show inside with all the tools jumbled up. We’re working on a possible solution for that. In the meantime, the handlebars sure are a convenient spot to stash tools on a trail bike, and that’s about the heaviest thing you’d ever use it for which is a good thing for testing. What else are folks storing in their handlebar bags? Snacks, sunglasses, phone, wallet, inreach…

Here’s the old prototype (top) I’ve been using, and the newest prototype (bottom).

Here’s the rear view, with the new version on the right. We added vertical slots so you could attach a Voile strap around your handlebar mounts or risers, running perpendicular to the main straps. I was thinking that would quell the bounce, but it didn’t really work out that way, although maybe it helped a little.

Eventually, I did find something that stops it from bouncing: wrapping a Voile strap around the middle of the whole bag like a belt. Yeah, it’s one more step to get into the bag, but man that thing stays put. Maybe this is something we could build into the bag with an over-strap. I don’t even think it has to be a Voile strap necessarily, it could be just a velcro cinch strap with no elasticity. If you just have a few cliff bars, or if you’re touring not trail riding, you wouldn’t need the strap. This would be an option for heavier loads and more aggressive riding on a smaller bike. I mentioned this to Andrew and he has some ideas.

Body Armor P1 Samples

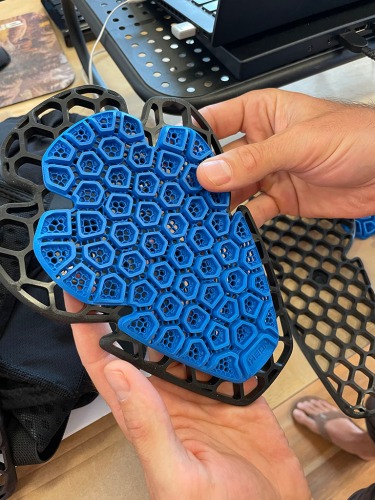

We got first round samples for a few items of the new Rheon body armor (black in the pics below). This is something I was really excited to get my hands on and I gotta say that although they’re not much to look at right now and they’re still pretty rough, they did not disappoint. To me, that’s further evidence that we’re finally working with the right armor partner.

The pads themselves (shown below) are just for approximate sizing, they were 3D printed not molded. The final version will be cupped to shape, and it will have a similar second layer of finer honeycomb, like what you see in the blue samples below.

The final CE2 pads will look more like these Rheon back protectors, which are SO cool.

This is two different sample sets of knee pad concepts plus one sample set of elbow pads.

Knee concept #1: this is the direction we are leaning, a zip-off tube.

Knee concept #2: this one we really liked the look of as a drawing, but functionally we’re not as crazy about it now. It’s more of a classic moto knee pad design, but made from soft, flexible materials rather than hard ones. What we don’t like is that there’s too much going on with this sample: straps, zippers, seam binding, etc. That is a lot of things adding bulk, potentially rubbing on your skin, and bunching up. It does look cool though.

Just for fun we pulled out some old D30 armor samples we have sitting around to compare the thickness and weight. The Rheon is obviously way lighter and thinner at this stage, although it’s not a fair comparison yet as these 3D printed Rheon prototypes aren’t the final CE2 product, and I’m not even sure D30 still sells these old Xergo pads, which were especially large and bulky. That said, you could double the thickness of the Rheon pads and they would still be substantially lighter and more flexible.

It’s pretty cool how pads made from non-newtonian liquid turn hard on impact. You can slowly push a hammer into the soft pad (which is what we’re doing in the pics below), but when you actually hit the pad with a hammer, the material turns hard. Both Rheon and D30 use the same technology to accomplish that, Rheon just uses a higher percentage of that technology in a smaller, more ventilated, more flexible package. It would be cool to have a little ‘testing center’ in our show booth where riders can play with all this stuff at events.

These are the impact shorts. They fit surprisingly well for a P1. The pads seemed a little low and forward, but that’s an easy fix.

Between the new Graph base layer, the new elbow and knee pads, and the impact shorts, it was pretty cool to be totally kitted in Mosko gear for the first time including armor. Everything but the socks.

After 7 hours on the bike I had some feedback. Mostly it was normal stuff you’d expect on a P1. The fact that these prototypes were even test-ridable at all, was a notable victory from my perspective.

I had some issues with the elbow and knee pads binding in the crux of the joint on the inside, and also some issues with the tops of both pads slipping. There are some sizing issues, and strap placement issues, and materials issues, and trim issues. Normal stuff, most of which we were already aware of before riding. I took lots of notes and pics. But overall my first impression was surprisingly positive and the issues were minor. One thing I really loved, was the materials package we’re using.

Here you can see the thigh band slipping down and working its way under the pad while riding. The armor pad itself stayed in place even as that was happening, because the calf portion of the tube had a solid grip and didn’t budge.

A Gear Hauler

It’s time to tackle a gear hauler. Everyone has one, everyone needs one, most of us aren’t entirely satisfied with the ones we’ve owned before, and the assortment of available options doesn’t change much. It’s a fun bag to think about. I took this pic of what I personally take to the trailhead for a ‘normal’ afternoon of riding on our local trails. It’s a LOT of stuff, way more than other sports.

The gear above easily packs out this 145L duffle I’ve been using as a gear bag. That’s a huge duffle, and that’s just for a day of trail riding. What about a week in Moab or Baja? What about fly-in trips? What about airline checked bag size (62 linear inches) and weight restrictions (50 lbs)?

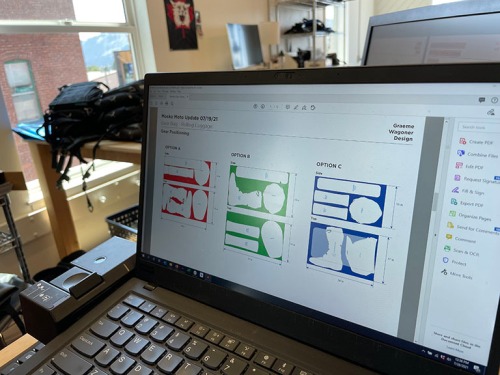

We reached out to a pro named Graeme that Dave, Scottie, and Andrew know from DaKine. Roller bags and gear haulers are his specialty. Graeme: welcome aboard and thanks for helping! The project already feels like it’s off to a great start.

We found ourselves resuscitating this ancient DaKine split roller from my garage, which was created way back before airlines started cracking down on their weight and size restrictions. This bag was ahead of its time. There were some minor technical problems but maybe they’re solvable now. It was a super cool concept that never fully caught on. The bag splits in two: both sides can be checked separately or tossed in a pickup, then reattached at the destination for transport.

Heavy duty rollers.

We like the idea of multiple insert bags that velcro in place but which can be removed and packed separately if needed. The idea is that for trailhead use, the bag can be like a normal gear hauler with a natural spot for boots, helmet, goggles, etc. But for longer trips (ie Baja/Moab) or fly-in trips, it splits and expands into a cavernous space for all your stuff, and takes full advantage of every inch of the 2 x 62 linear inches that’s included with your international flight. You can shuffle things between the two bags to keep each one under 50lbs.

Laptop Cases

For over a year now, we’ve been talking about creating some kind of moto-specific adaptation of our buddy Juan’s cool carbon fiber laptop cases. The project hadn’t progressed much until recently, because both Juan and we have been distracted. A few weeks ago Juan visited the shop, and we got excited all over again.

A sticking point previously was the high cost of carbon fiber. As cool as it is, we felt like a $350 case was bound to have limited adoption. Many of us are carrying older, beat up computers and/or smaller netbooks or iPads for moto travel. We felt like the cost of the case shouldn’t exceed the value of what’s in it. Last week we received some aluminum prototypes that look great. Aluminum reduces the cost by approximately half, while the original carbon cases will still be available from Juan directly on his website.

‘

‘

We have all the parts and pieces now to assemble three different sizes for testing.

One thing about carbon, it sure is light! The aluminum cases currently weigh about 1.6kg (compared to .9kg) but we can reduce that by using a thinner aluminum sheet and adding cutouts. The current aluminum panels seem a bit thicker and heavier than we really need.

Basilisk & Rak Updates

The Basilisk & Rak are both back on the design table, so if you have any special requests please chime in. Especially if you own one of these already!

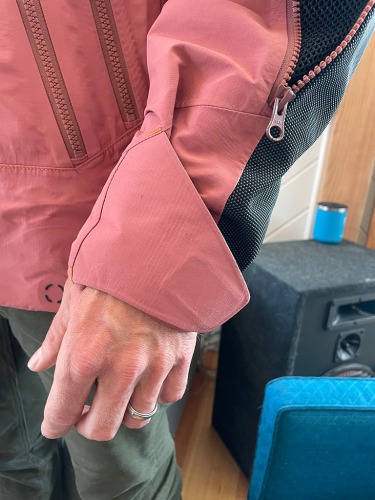

One of the challenges with redesigning the Rak, is that simplicity is the goal. Yet we feel like now that we’ve been riding with it for over a year there are a few things we want to add. One of them is a kangaroo pocket. We didn’t include this on the first version and we wished we had. It’s a partial nod to the top-down storage pockets on ADV jackets, and also a partial nod to the classic Anorak styling. Plus we pick up an extra layer of waterproofing on the front of the jacket, which shouldn’t be necessary but never hurts. The coolest thing about this pocket is that it’s so big, that you can easily grab dinner at your last gas stop of the day, or a couple beers, or whatever and stuff it in there. It’ll be the largest pocket you’ve ever had on a moto jacket guaranteed: it’s a large, functional storage spot and I have no doubt that it will get used in ways we haven’t even imagined.

You could even do this, although I’m not sure why you’d want to.

We’re also adding a removable hood. After using the Rak on several trips when it rained, we missed having a hood around camp, and if we’re adding a hood for off-bike use then we might as well make it helmet-friendly too. The first version you see here was a serious storm hood, like something you’d take to the ski hill. This was overkill, plus it doesn’t play well with helmets, so we’re taking it down a few notches on the next round.

The Basilisk pant is getting a massive forward-facing thigh vent, although we’re still working on the details. It’ll probably have a sizable storm flap, and the top flap will probably snap back when open. Here you can see Scottie testing two different styles.

We tried this cool magnetic waist closure but it doesn’t grip very well.

The Basilisk jacket is in for a complete overhaul.

We added a radio/inreach loop.

We added forearm vents in addition to bicep vents.

The wrist cuffs are huge. Too huge.

We’re using this awesome heavy-duty tricot on the inside, which unfortunately the mill is saying will be very hard to get in the small quantities we need, but we’re pushing for it anyway.

We added a little hidden money/ID stash pocket behind the label.

It seems like a lot of zippers, but there’s nothing here to delete. We might storm-flap the two main chest vents to reduce visual clutter and provide additional grime/water protection. The main center zip already has an internal flap with double gutters, but those vent zips are pretty exposed and they go all the way through. On the other hand, flaps block a lot of airflow and make the zippers a bit harder to operate. This needs testing.

I took the Basilisk – in this epic ‘salmon’ colorway that eVent supplied for our samples – out for a 4 night solo trip on the KTM 1290. It was summer and very warm outside.

This is how it looked with all vents and the main zipper open. After a while of riding like this to test the full extent of the airflow, which is considerable, I did what the jacket was designed to do and stashed it on the bike. It stayed there for most of the trip except in the chilly mornings and some brief periods of rain. The Basilisk doesn’t roll as small as the Rak, but it has a lot more abrasion protection and it still gets pretty small compared to most other moto jackets.

The leather on the pants had some major scuffs after just a few days. This is a known issue. We’re working on sourcing a new leather for all our pants. It doesn’t wear all the way through, it just surface-scuffs too easily.

The trip itself was a blast. It was a mix of woods and desert, high speed pavement and dirt. I came back really stoked on all the revisions. The Basilisk is an awesome kit. I love it now like I did the first year it came out. It’s a good clean shell for enduro touring made from the best materials, with just the basic features you need and nothing else. The eVent breathes better than anything on the market, and with the superfabric overlay on the shoulders, arms, chest/back, knees, and butt, it can take a serious hit.

Trail Pant & Softshell Jacket

We have so many versions of the new trail pant either in-house or on the way that I can hardly keep track. We ultimately decided this should become two pants: one for extreme hot weather and desert riding, and the other for 3-season athletic trail riding and mountains. It’s a little confusing, because for trail riding – which is sportier than touring – even a 3-season pant will have some mesh. Trail riding, we run hot.

This pant is getting closer to the right shape and fit, but almost everything else needs to change. The blue is hot and itchy, the black at the calf feels like lingerie, we’re eliminating a pocket, and the waist cinch is still a place-holder. We’re inching toward a pant we like. The end is in sight.

These are a size too big for me but you get the idea. I wore them until I couldn’t take the itching.

This is another version of the same pant, which Andrew wore in Death Valley last year. We like the materials package on these much better. The black is a sturdy, stretchy, dense mesh from Schoeller. It’s tough and breathable. We think that mesh is a winner, and could be great on a 3-season trail pant.

We’re still working on the softshell trail jacket. It has two hand pockets, a lumbar pocket, and a chest pocket, all of which transform into vents. You can use them as either vents or pockets but not both, since stuff would fall out.

IR Pant

I have these pics of the updated prototype of the IR pant. “IR” stands for “Integrated Removable,” because it’s a shell kit (no inside liner) with the ability to quickly and easily add or remove Rheon’s soon-to-come armor pads. I only got to play with them for a day before they were sent to Brittany up in BC, but I liked what I saw. When we get them back we’ll take them riding.

Back on the Road!

After an exceedingly weird and stationary year in 2020, the Mosko road show is back. We thought we’d be back in April but some early events got canceled, while others were moved to later in the year.

The first event was a meetup in Portland at the legendary See See Motor Coffee Co. Most of the Mosko team participated, and a ton of our friends and fellow riders from the area showed up. It was awesome to see everyone in person finally! Thanks to all who came and made this event a success.

Ash and I did a brief presentation on Mosko’s “Year of the COVID.”

From there, after a week with friends in the desert, we headed to Great Falls Montana for the BMW Motorcycle Owners Association rally. This event is always killer. It was packed and so, so busy. We were out of stock on nearly everything so we didn’t take orders, but it was great to see everyone and show off the new gear. I can’t think of a better way to kick off the 2021 show season.

It rained hard one day so we packed up the booth and went inside to check out the other vendors. Everyone was happy and busy.

This is our buddy Eric in the bottom right (in the cap) with his new business Ruby Moto. They make badass accessory lights, and the BMW MOA was his first event. His filthy GS display got lots of attention.

Takeout dinner with the Mosko team on the last night; this is after setup, three days in the booth, and tear down; squeezed between rigs at the Great Falls fairground RV park. It was a great show and a great feeling. This team works hard!!

After BMW MOA, we headed to the Northern California IMS show at Sonoma Raceway. This was the first of 9 outdoor Progressive IMS shows, and the first of their new summer format. In the past, IMS shows always happened indoors in the winter. Last winter they were canceled due to COVID, so the organizers did something they wanted to do anyway: changed the IMS to an outdoor summer show, which is better for bike demos.

This was our first opportunity to setup our new awning, which arrived in parts & pieces just days before leaving. JC installed it just in time. It’s a legless awning made by EIDE Industries; the kind of thing you might see at a NASCAR race. It’s a sweet piece of show kit and remarkably compact to transport and easy to setup. The awning held up great in Sonoma’s strong afternoon winds, and the booth looked better than ever.

This is the Sonoma show from above.

The foot traffic in the vendor area was not what we’d hoped, although we heard the OEMs were happy because their demo rides were fully booked. Attendance was around 14,000 people, which is a large number of people no matter how you look at it, but it’s still only about half of the attendance at the last NorCal indoor IMS. It felt much slower on the vendor booth side of things. Maybe people were doing demos and leaving right after, maybe there was an issue with the flow and layout of the event, or maybe it was the wrong weekend, wrong location, insufficient marketing, COVID, or whatever. Who knows. The IMS planners are some of the most experienced operators out there, they’re working on it, and I think we’ll see better outcomes for the rest of the tour.

In Sonoma we had plenty of time to tinker with the booth, chill, watch movies, brainstorm ideas for the next show, take naps, shoot the shit with friends in nearby booths, etc. We had a good time and it was cool to test the new setup even if it was sort of a disaster financially. Being outside is a lot nicer than being inside, so we really want the outdoor format to work. We’ll do everything we can to make that happen.

After IMS we headed to PJ & Co in Reno, NV for our first-ever Reno meetup. Man this was such a blast. The owner of PJ’s is super cool, and he already knew Mosko and had some of our gear. We offered free drinks and appetizers on the Mosko tab, and about 50-60 folks came through over the 5 hours we were there. There was plenty of one-on-one time and we made some great connections with Reno riders. As soon as we get some inventory, we want to pack the calendar with meetups.

Rather than riding in the main Mosko rig, I followed along with my van and stopped to mountain bike and car camp along the way. That was a nice way to break up the road trip and squeeze some extra summer out of the summer.

The smoke in Northern California and Southern Oregon was bad. It almost reminded me of last summer in the Gorge, although not quite as bad as that yet.

It’s weird to do shows without inventory. A lot of other companies backed off on their show and marketing plans for the year. We briefly discussed that, but decided to get on the road regardless. Shows for us are less about actual sales and orders and more about the connections we make and the product feedback we collect, plus spreading the word about who we are and what we’re up to. If all goes according to plan we should be fully stocked soon, and we can finally get these supply chain issues behind us.

Next stops: Chicago IMS (Aug 20-22), Overland Expo Mountain West (Aug 27-29), and Carlisle, PA IMS (Sept 10-12). Hope to see you out there somewhere!

Harley Davidson Pan America 1250 & Mosko Moto Backcountry Panniers

Big thanks to the rider who arrived in Reno with his new Harley Davidson Pan America setup with Mosko bags. He answered a question we’ve been getting a lot lately, which is this:

‘Will the Mosko Moto Backcountry 35 panniers fit the Harley Davidson Pan America pannier racks?’

The answer: ‘Yes’

I’m trying to use all the right keywords here so that if someone googles that question they will find this post and pics. The stock Harley Davidson racks are made by SW Motech and they have the classic SW Motech shape, which our Mosko pucks were designed to fit. There is no special adapter required. Plug & play. Looks great.

Assorted Pics

Here’s an assortment of other pics from the last few months. Some even have captions. Enjoy!

Welcome lunch for Bear.

Bear took the company truck & trailer out to Jackson, WY to get all his stuff and relocate it to White Salmon. He picked up a new bike for Jack on the way.

Here’s Donzi and Roland, the other 2/3rds of Ryan’s family, in the desert a few weeks ago.

Jesse Rosten aka @onelostmoto

The new showroom is coming along well. This should be done in the next few weeks.

HVAC upgrades. Thanks Jonathan! It’s awesome to have friends from other parts of our lives pop up in the Mosko story. Our good friend Jonathan did all the HVAC work in the new-to-us (but otherwise quite old) building.

We have this awesome old door, which could be an original from the early 1900s construction, but you cannot fit a GS through, so unfortunately it’s got to go.

Minibike maintenance

Proto as fuck. Another of Joel’s DIY carbon creations (Joel is Sammy’s BF).

Ash’s 30th birthday dinner was roadside iced tea and tacos in Madras, OR on the 8 hour drive to the desert. This is not everyone’s idea of an epic 30th, but we made up for it later.

Our graphic designer Dan Cox donated a couple new chairs to the marketing office. These will also be used in his upcoming wedding (congrats Dan + Jo!). They help class-up the place, but that carpet’s got to go.

Our buddy Russ patented this cool new inflatable awning design for vehicles using kiteboard technology and materials. It can be mounted anywhere on any vehicle: car, van, or truck, on the back, side, etc. It packs small and deploys with magnets, no fixed mounts are required. You can easily move it between vehicles or connect it to your buddy’s vehicle. It’s a neat system. This is his first prototype. The company is called ‘Daylodge,’ but there’s not even a website yet. Keep an eye out!

New graphics kit on the Mosko T7. It was a puzzle to apply. Nice work Ryan!

More Joel creations.

Photo credit for this and the desert shots above @traceymac99. Thanks Tracey!!

Warranty and Crash Replacement

We never cut corners during development or manufacturing, so we stand behind our products. If one fails due to a problem with materials or workmanship, we’ll make it right.

Your are successfully subscribed for email notifications.

Notify me when available

We will send you a notification as soon as this product is available again.

Your email is required

We don't share your email with anybody

x