Your Cart is Empty

Luggage

Apparel

Events

The Mosko Blog

Boats, Planes, & Preorders

October 06, 2021

Our little Mosko micro-multinational ship is getting tossed on the large and stormy seas of international trade. It has not been boring.

In Vietnam, the southern area around Ho Chi Minh City (which includes four factories we work with) was completely locked down due to COVID until October 1st. Factories and transportation were idle and we lost about a month of production time. Now businesses there are reopening, but they’re hampered by a lack of vaccines, and we’re not sure what the raw material situation will look like when the dust settles. Production is also delayed at our main fabric welding factory in China, where they’re experiencing shortages of both labor and materials simultaneous with a surge in orders. In Bangladesh, we’re about to submit our 2022 PO while waiting on several 2021 styles that we’d hoped to introduce back in April.

Shipping from Asia to the US is also problematic. As you may have seen on the news, there’s a large backlog of containers and container ships on both sides of the ocean, as well as a shortage of the containers and ships themselves due to that backlog. The price of water freight has risen 500%, plus it takes 2.5x longer to move a container from Asia to the US than it did before. In the rush to get inventory, many companies are moving to air freight, bidding those prices to record highs as well. Normally we allocate about 5% of our product cost to cover shipping. The last shipment we received by air cost 35%. We just booked a second one at 55%. We received quotes as high as 85%. It’s nuts.

An alternative to air freight is to deal with the much longer shipping times of water freight, which means we’d be out of inventory for a while. Even at the current unheard-of cost of $20k to move a container, containers are still a bargain compared to air. With containers, we could start collecting preorders in November/December for delivery in February/March 2022. What I’m not crazy about, is the idea of putting our shipments at the end of a long line of international trade goods, and nobody knows whether it’ll get better or worse while we wait. Once a container is delivered to the port, you can only cross your fingers and start counting down the days. That’s what we were doing all last summer. My feeling after that was ‘never again,’ but freight at 50-80% of FOB is not ideal either.

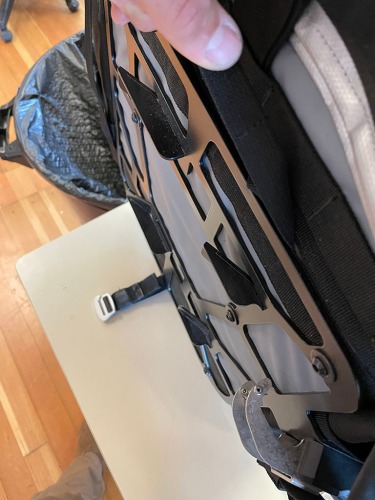

While we noodle through these manufacturing and freight issues, we’re also doing final assembly on our last shipment of panniers. That shipment arrived only partially assembled because our factory was closed. Here in the U.S. and Europe we’re adding logo plates, locking bars, and mounting frames. The mounting frames are especially challenging. At the factory, they punched six holes in the back of each bag, through all the various layers of plastic, fabric, and foam. When the bags get packed for shipping, the different layers all get misaligned. It takes a surprising amount of effort to realign the layers and connect the six bolts with the tee nuts inside. It’s a very tight squeeze. Last I heard the record time for a single bag – not including the locking bar and logo plate – was 8 minutes. The average is more like 15 minutes. A brand new worker averages 30-60 minutes, and still requires occasional rework by a more experienced hand. At $25/hour plus taxes, management, rent, and trucking to/from White Salmon, it’s all adding up.

We spent about a week assembling panniers at our warehouse in Portland, but we had a hard time finding helpers there due to the tight labor market, plus the 1.5 hour drive each way is a downer. So instead we rented a small warehouse space in White Salmon for a few months, and trucked all the inventory here. We have 4-6 people working over there now, and we estimate it’ll take another 3 weeks to finish. In the meantime, the Vietnamese government is loosening its COVID restrictions and our factory is reopening. It’ll take a minute, but there’s a light at the end of this tunnel.

These pics are from the initial assembly week at our contract fulfillment warehouse in Portland.

This is at the new location across the street from our shop in White Salmon.

Your mission, should you choose to accept it, is to get these 6 bolts, washers, and tee nuts through a mounting frame and bag…

… including 6 of these misaligned holes.

Ames made this funky wood jig for mounting the locking bars.

One day when we’re old and grey, our grandkids will sit on our laps and ask what we did during ‘the great supply chain crisis of 2021.’ We’ll have so many stories to tell them. Stories of freight and logistics, factories, and viruses. Stories that will put them directly to sleep  .

.

Donzi Kater: Welcome Aboard!!

Donzi Kater – far right in the pic below with Sammy & Jenn – recently joined our CS team. She’ll be working mostly from home with occasional office days. Before Mosko, Donzi spent 5 years at the outdoor retailer REI as a Sales Lead, Visual Merchandising Specialist, and Outdoor Instructor. She has an AA in geology and is certified in wilderness first aid. Donzi and Ryan (Mosko’s Field Sales Manager) are married. When their son Roland is old enough we’ve got a spot for him too. Welcome aboard Donzi!

This pic from the last post, is Donzi and Roland in the desert last summer.

New Products

Rak Jacket

Here’s Andrew testing the latest Rak prototype on a trip we did a few weeks ago. This jacket is nearly ready. It’s getting a kangaroo pocket and a hood, and the side zip extends higher up the torso. The Rak pants are staying the same.

Barfly

I took my Patagonia Houdini shell as a proxy for the direction of the new Barfly jacket we’re working on to replace the Deluge. I was surprised by the overwhelmingly positive experience of committing to such a light jacket for the trip. No holes or tears so far, and it did a great job of cutting the wind. Plus I love the way it packs away on my bars. The Houdini isn’t waterproof, whereas the Barfly will be.

I’m also wearing a prototype of our new Surveyor trail pant in this pic. The knee panels and butt are a stretchy Schoeller mesh, which we love.

On a second trip where it did rain, I rigged my Deluge on the handlebars with a larger Voile strap, which also worked great, although it’s bigger obviously.

The Wildcat Backpack

We have a new prototype of the Wildcat. Man this bag has been a long time coming. We’re more than ready. I just used it on an ultralight overnight trip. I especially loved the expandable beavertail, which significantly increases the carrying capacity. Also the chest rig, which keeps things like snacks, phone, battery pack, and InReach close at hand. When you’re all bundled up and armored, it’s great to grab a Cliff Bar on the trail without removing your pack.

These are set-it-and-forget-it backpack strap adjusters inside the pack. There are also on-the-fly adjusters on the chest straps themselves. This is our way of addressing the challenge of fitting a huge array of different body shapes both with and without body armor.

We’re looking at some alternate logo applications to replace this basic screen print. Possibly a sewn-on label.

This little bungee stops your InReach or other beacon from flopping around when you’re not using the chest rig, and you want to mount the beacon directly to the shoulder strap.

Andrew’s little InReach carving. Isn’t it so cute?

The tool holder pockets and straps work great for an air pump and tent poles.

An issue we’ve been tracking on the chest rig, is that the magnetic buckle we’re using has a tendency to attract metallic particles and dirt and then – when impeded by those things – not to fully engage. You can see the tiny rock attached to the nipple in the pics below. I just rubbed the nipple in the dirt and the magnet found the rock.

I’ve personally had a few situations where the chest rig disconnects while riding. It dangles awkwardly and you have to stop to fix it. Now I blow out the nipple after it touches the ground, but it’s easy to forget to do that. We’re at the point of placing a PO and we don’t have a good backup, so it’s really just a question of whether we order the chest rig or not. The chest rig is something we’re all loving, and it’s a major design feature of the pack. It would be weird to make the Wildcat without it, so we’re planning to move forward with the buckle. We’re looking to add a secondary velcro attachment to support the buckle. If the nipple is only partly engaged, the chest rig will stay attached with the velcro. The partly engaged nipple holds it in place while the velcro keeps it from dangling.

This is not the first time we’ve run into this metallic dirt issue with a magnetic buckle but it’s the first time we’ve pushed past it. The velcro should fix this. Magnetic buckles… the struggle is real. When they’re working, they’re great.

Here are some shots of Andrew riding with the smaller 8L version of the wildcat.

Scottie mounted the chest rig on his DaKine Seeker pack, which is something we might develop further in the future: ie the ability to apply the chest rig to any pack. He has also been using it with a neck brace with no issues.

Gnat Handlebar Bag

I’ve been using the latest Gnat prototype to carry tools on my trail bike. I’m still running a Voile strap over the top, which keeps it solidly anchored. Andrew is testing a built-in strap on the next version to make it feel a little less tacked on.

We’ll be offering two sizes of the Gnat. Here’s the small one.

Here’s the big one. I was happy to see it fits on my 500 next to the Gnome.

Reckless Mounting & Construction

We’ve been gradually building toward what may ultimately become a v4 Reckless update. The new version would incorporate Voile straps on the legs, the Knob mount in the center, and a stiffer construction for the harness. We may release these upgrades individually as they become ready, but if we do them all, the finished version will justify a v4 designation.

I’ve been using the Knob and Voile straps for a while now. It’s a significant improvement to the stability of the bag. On the exhaust side, I run the strap to a cleat that tees off my subframe bolt with a small spacer. On the non-exhaust side I go straight to the frame. Ultimately we would make these Voile straps in custom lengths but for now I’m just using two of our larger straps connected together. Anyone who has a Reckless bag currently, can try this.

On my 300 I bolted the knob directly through the plastic fender.

This is what the latest version of the Knob looks like (left). It’s smaller.

The Knob mount looking top-down.

In this version of the R80, we changed the centerpiece to aluminum. It looks super cool. However, it’s also heavy, which is the opposite of our intent. It also has the potential to deform in crashes. Still, it’s a cool idea and potentially workable.

A second possibility is to make the harness from composite, like this prototype I tested a few weeks ago. It’s light, tough, and has a high level of heat resistance, while still providing more structure than the current Reckless. Also it can be thermoformed. We’re really digging the look and feel of this one.

BMW Mounts

We’re reviving an old project, to develop mounts for the Backcountry Pannier that click directly into the BMW pannier rack mounts with the little tabs. Here’s the current status of that prototype. The latching mechanism is the final riddle to solve.

Low Profile Pucks

We have three different prototypes of a low profile puck design for the Backcountry Pannier. The main difference between them is how the threaded insert attaches. This puck will start as a limited run for riders who need just one or two of these to clear their exhaust. If it works well, it might ultimately replace all the Backcountry pucks.

Navigator Update

The Navigator cell phone pocket is ready for an update. I’ve personally been using it for navigation on every kind of trip from trail riding, to dualsport, to big bike, to international travel for several years. It’s still my favorite way to navigate (vs a hardwired GPS or a handlebar phone mount) but there are some things that could be better. For example, glare from the sun obscures the screen when the sun is high and/or when the vinyl gets old, scratched, or dusty. Also, operating the touchscreen through the vinyl is imprecise at best. We’re looking for ways to eliminate the vinyl altogether. One thing we came across is this rubber cell phone holder I’ve been using to hold a phone while fishing. It fits any smartphone and is quite secure. If we retained the phone with something like this, maybe we could get rid of the clear vinyl. You’d be viewing and touching the screen directly.

New Scout 25 Update

The Scout 25 is up for a redesign. We have an idea to do something like the pics below, to eliminate the aluminum plates and pucks. This would reduce weight, complexity, and price, and also make it easier for folks who want to swap back and forth between hard and soft bags. We’ll pull on this thread and see where it leads. This could be cool. Andrew’s on it.

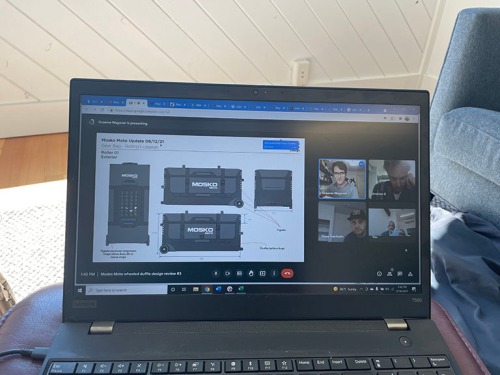

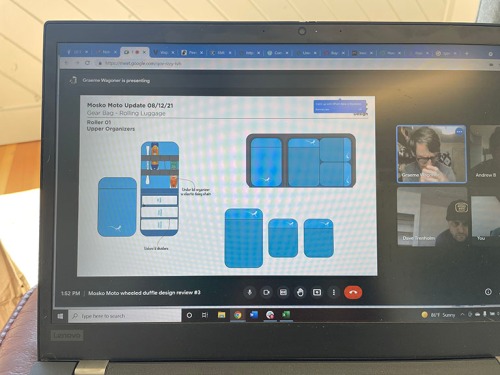

Gear Hauler Bag

For the gear hauler, we’re narrowing in on a concept that’s nearly ready to prototype. It’s a two-piece, plane-and-truck-friendly roller bag with a separable top and bottom, and a variety of smaller insert bags for boots, helmet, etc. This is a large and complicated bag with a lot of moving parts and many experimental features. It’ll take a minute. Can’t wait for this though: we definitely need a gear hauler.

Laptop Cases

The current aluminum version of the laptop case is too heavy. We’re lightening them up a bit. We lost some time to researching alternate protective foams, but we’ve come back around to the Poron XRD.

2022 Apparel

Last week a crew of us got together to discuss the 2022 apparel line. Scottie & Julia put together a presentation and we walked through each item including forecast quantities, design features, materials, colorways, and pricing.

Most of the new and updated apparel items have been covered in prior posts, but there was one internal debate that was particularly interesting. It has to do with the mesh pant. You might remember the green and black prototype on the far right in the pic below, which Andrew used on our team ride in Moab last Spring. We all liked it immediately, there was an instant visceral reaction to the main body mesh. It’s dense, abrasion-rated, and burly, but also stretchy, well ventilated, and comfortable. Since then we’ve tried three other materials packages and we’ve come back around to the Schoeller.

The problem is that the Schoeller is expensive. Schoeller is a Swiss company with European manufacturing costs. Their products are nice but pricey. Using this mesh pushes the price of this pant higher than the Woodsman, which also uses Schoeller and has a waterproof membrane too. We were shooting for $250 but with the Schoeller mesh it’ll be around $350. We could easily substitute a different mesh and shave off $100, but none of us can muster any joy in that. We like this material: we like the durability and stretch, and we like the higher density. It feels like it would widen the range of weather and terrain scenarios where we would reach for this pant, from singletrack day rides in the desert to multi-day trips and even pavement. It’s like an equivalent to the Woodsman, but mesh.

Things like this test our internal policy of not designing to a price point. Because we still need to make sure every feature, construction element, and material justifies its cost. Is a pant made from this mesh really worth $100 more? Is a $350 mesh pant even viable? We think ‘yes’ on both. There are other mesh pants out there at this price point, so we’re not alone, and we’d definitely pay more for a pant that we’ll reach for more often. We’re moving forward with the Schoeller. Hope it’s the right call.

Arcade Belts

Our ongoing internal debate about belts vs waist adjusters continues. We have yet to find a waist adjuster we like. Over the last 6 months we’ve tried 3-4 different styles on prototypes and none of them worked. We just got a ratchet-style that’s ok, but then we realized it’s the same one used on a popular trail pant made by another apparel company, which feels weird, although we’re not exactly ruling it out either. We also have two seasons of experience with the Woodsman pant, which has a waist adjuster that never really worked the way we wanted it to.

Several folks at Mosko have been wearing these elastic belts made by Arcade Belts. Sammy convinced Bear and I – the staunchest old school leather belt fans at Mosko – to give them a try. I’ve been wearing mine for at least three weeks now and I haven’t gone back. I checked with Bear yesterday and it turns out that he’s still wearing it too. A belt like this would be sportier and lighter than leather but will still keep your pants up. We could skip the waist adjusters, add belt loops and snaps like the Woodsman, and offer a belt like this as a $30 upgrade option.

Fender Bag Attachment

Scottie and I were looking for a way to attach gas bottles to our trail bikes. Here’s what we came up with. First we used a hand drill to make slots in the ridgeline of our KTM front fender. Then we connected a 5L aux pox drybag using two large voile straps. This system worked great. Maybe someday we’ll make a purpose-built bag that mounts here. I’m just sharing this in the meantime, in case anyone else wants to try it.

First Aid Kit

Andrew is brainstorming ideas for a waterproof MOLLE first aid kit. I saw a draft of the drawings earlier today. It’s awesome. More on that soon.

Mosko US & EU Roadshow(s)

Ryan, JC, and Azure have been leading the charge on the Mosko roadshow, with the rest of us dropping in as needed to man the booth. Since that first Portland meetup in June, followed by the BMW Rally in Montana, we’ve been to Sonoma, Chicago, Loveland, Pennsylvania, Flagstaff, and Dallas, with meetups in Reno, Kansas, and Santa Fe. Right now JC is in Little Rock, AR on the way to Nashville, TN for IMS. Nashville is the first of three stops in the SE, with the other two in Atlanta and Florida, plus meetups in Miami, FL and Charlotte, NC. After that, we’ll return to the west coast for the So Cal show and then a much-needed break.

Here are some pics from Chicago. This year the IMS moved from the indoor convention center to a spot called Goebertt’s Farm (aka Goebertt’s Pumpkin Patch) about an hour outside the city. When we learned we were doing a show at a pumpkin patch we had a good laugh about that, but actually it was an awesome venue. Attendance was excellent. Here’s a map.

We were next to the pumpkin train, down the road from the pumpkin eating dragon. I never made sense of it on the map but maybe trains and dragons move around. We had a great time on the jumping pillow.

We ordered these awesome heavy-duty inflatable couches made by the rafting company Aire. You can actually float rivers on them. We’ve been leaving them around for people to sit on, and occasionally pulling them into the booth for seating during presentations. They’re popular. If we were selling these they’d be a hit.

This action figure for kids will be available in toy stores soon. It’s called ‘Ashley: Motorcycle Show Warrior.’

This is our new ‘Stimulator’ jacket with patented ‘fun button’ technology. It keeps you awake on long pavement stretches  Actually, it’s the new Ectotherm heated jacket, which we are still waiting to receive.

Actually, it’s the new Ectotherm heated jacket, which we are still waiting to receive.

Our booth in Chicago.

We heart lizards.

Teardown takeout dinner, a new Mosko tradition.

After Chicago, the team and trailer headed to Loveland, CO for Overland Expo Mountain West, while Ash, JC, Lee, Bear and I headed to Nevada for a prior commitment on the Black Rock Desert.

Just before we hit the road for Nevada, we got a late-night call from Ryan. Disaster had struck. A strong windstorm blew through the Loveland venue with 80mph winds, and our fancy new trailer awning was broken, torn, and flapping in the wind. This was I think around 9-10pm. He texted these pics.

Aww man, bummer! Another twist in the rolling truck, trailer, freight, and flight adventure that is our traveling Mosko circus. Ryan, Scottie, Jack, and Forest packed up the broken pieces, setup our two old EZ-ups, and quickly reset the booth, so that by the time the show opened the following morning only somebody who’d actually seen the carnage would know the difference. I’m proud of how our team took that setback in stride, rebuilt the booth, and pulled off a killer show anyway. Nice work all!

The next event we needed the awning for was Overland Expo West in Flagstaff. It’s a big show and we booked a big booth, assuming we’d have the trailer and awning. Looking at those pics from Loveland I thought the awning was done for. Plus the trailer ran over a railroad tie that fell off a truck on the highway and broke an axle coming home from Pennsylvania. But JC found a vinyl shop to patch the awning. Then he found a metal shop to weld the rafters. Then he got the awning manufacturer to overnight replacement parts. Then he consulted a trailer manufacturer on the mounts, and made new ones. Then he welded the broken axle back together himself. This was in the week before OX. It was an impressive sprint.

By OX, we had our awning back. It lives!! Amazing. Thanks JC!!

Overland Expo was a blast as always. Incredible how this event has grown. Most of the attendees are there for the 4x4s, but many also ride, so there’s a lot of crossover. We did several in-booth presentations on topics like ultralight moto packing and motorcycle apparel tech. We also did a packing presentation in the main tent.

We all stayed together in an Airbnb 10 minutes away. After a long day in the booth, a sofa, takeout food, and a movie is about all I can handle these days. Side note: the Evel Knieval documentary is awesome.

On Sunday it rained, and we finally got to unfurl these cool fabric rain gutters, which I was secretly looking forward to because I think they’re cool. The rain wasn’t great for show traffic but by then we’d already had two very busy days.

Taking advantage of the slow start, Ash and I went wandering. Out of 400+ vendors, there was one thing we were looking for, which was a nice shovel to keep in our 4×4 van. There’s a company called DMOS Collective that makes these really badass folding shovels for offroaders. I’d read reviews and seen pics/videos online, but I wanted to see one in person. We found the DMOS booth, walked in, bought a shovel, and returned. About 30 minutes later Susan Pieper, the owner of DMOS, randomly walked into the Mosko booth and introduced herself. It turns out we went to the same school and have friends in common. She just stopped by to say hi, no idea that we’d just been in her booth. Small world.

Nice to meet you Susan! The shovel is so cool!!

Overland Expo was a big success. We wrapped up Sunday, packed up the booth, and had a chill post-teardown takeout dinner with Mike Spurgin from Taco Moto and Eric Waterfall from Ruby Moto. Our companies all have punchy two-syllable names followed by ‘moto.’ It’s a trend. How could we not be friends?

The next morning, Ryan loaded up the company GS to ride to Santa Fe for a meetup. JC hooked up the trailer and headed off in the same direction with Azure riding shotgun. Ash and I boarded a plane home. This was our 7th Overland Expo since starting Mosko, and it’s still a major highlight of our annual circuit.

Europe SKOG 2021

Silke shared these pics from the SKOG event in Sweden, with the caption: “Some pics from our last weekend in the “Swedish Rainforest.“ Great people, great event, great time!!! SKOG 2021”

I can’t wait till we can all reconnect again in person. It’s been nearly two years since any of us went to Europe, or any of the EU team visited us here. That will change soon. Last we heard was that restrictions will ease in November.

Also from Europe, this awesome pic of the EU team replacing a wheel bearing on the side of the road, while Silke responds to customer emails from her laptop. Nice one Silke. Full commitment!!

Bear’s Crash

A few weeks ago, Bear, Sammy, and Jenn went on a quick overnighter, leaving from White Salmon and heading north into the mountains. They had a lovely night under the stars and were coming back, when Bear entered a turn hot, slid off the road, and wrapped himself around a tree trunk. The result: a broken Fibula, 7 cracked vertebrae (the wings not the spine), three broken ribs, and a swollen liver. He spent two nights in the hospital. Now he’s scooting around on a 4-wheeled scooter. The prognosis: 8-week recovery and no surgery.

There are 20 of us on the Mosko team. Everyone rides, and we all do other sports too. May the injuries be as few and small as possible. Bear: it’s great to see you up and about. I’m just so glad it wasn’t worse.

Ultralight Trip

Last week Scottie and I consolidated our camping kits down to the bare essentials and headed out for a two-day technical singletrack loop on dirt bikes. The last time Andrew, Ash, Alistair, and I tried this we took Reckless 40s, but the gear slowed us down to the point where we had to continually help each other get through the technical bits. On that two-day trip, we covered less ground than we would typically cover in a single day of trail riding.

This time we weren’t going to make the same mistake. We consolidated everything into Reckless 10s and backpacks (12L pack plus beavertail for me, 15L pack for Scottie). We wanted the bikes to handle as close to normal as possible, but we also wanted to enjoy the camping experience and not be up all night shivering under a safety blanket. I was on my KTM 300 and Scottie was on his 350.

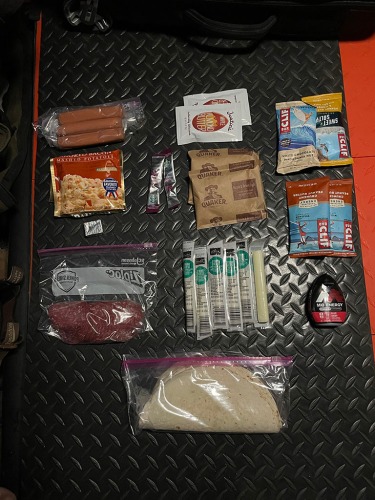

Here is what I originally planned to pack. No change of clothes, no tent, no stove, no water filter (water treatment tabs instead).

Here’s what it looked like all packed up.

Food for exactly two days. When the trip was over I had one tortilla and one piece of string cheese left.

We packed our Strata long underwear and Jackaloft Jackets in zip locks. We knew there’d be some cold/wet weather.

A few days before the trip, we realized it was definitely going to rain. We swapped our bivy sacks for 1p tents. I also swapped the Patagonia Houdini for a Deluge jacket, and replaced the plastic collapsing cup with titanium. Scottie brought a stove since it was too wet for fires. I also shrunk the first aid kit by removing duplicate and unnecessary items, and took a lot less TP than what’s shown in the pic above. I also brought a small squeeze-bottle water filter. Overall, considering we ended up with tents and a stove, I was amazed at how much we were able to fit into only 25-30L of space.

We van-camped in the woods Wednesday night. Thursday morning it was cold and rainy but we went anyway. Bad weather makes for good gear testing. We figured that if we could enjoy it in those conditions then we could enjoy it anytime. It rained all day and well into the night. We were tired, wet, and cold. We made camp at 4, climbed into our tents and sleeping bags wet, and spent 16 hours waiting for the storm to pass. The next morning was beautiful. The trails were tacky and fun, and the bright fall colors were on full display. I cannot wait to do more of this, just without the rain. The thought of exploring large, challenging, technical singletrack networks as thru-trips rather than day loops, gets me all fired up. Oh the places you’ll go!

Here Scottie is wringing out his gloves. ‘Waterproof’ in the sense that they hold the water in

In Other News

We’re so proud of Ash for completing her 2.5 month executive education program! Instead of mountain biking and kiteboarding, a huge part of her summer was spent on accounting, finance, statistics, and economics for managers through this course offered by Harvard Business School. It was intense. Congrats babe!!

Also: congratulations to Paulina on her new bike! A Honda CRF450L. The 450L is rapidly becoming a popular bike on the Mosko team. Ash and Andrew both ride them too, plus we have one as a show bike. Paul drove all the way to Montana to find this gem. Stoked!!

Foot-dragging small bike wheelie practice in the desert.

Ash and I visited my family in Maine this summer. Yes we ate lobster. Because I literally cannot get enough lobster inside me. It’s that good.

Removing samples from the Basilisk for CE testing.

Tough summer for our truck.

Ash and Dave, shooting product videos in our now ‘nearly complete’ showroom. I’m not sure it’ll ever actually be complete. It’s more of an ongoing work in progress. A lot has happened there since I snapped this pic, and more is happening now.

We met Johnny & Camille in a parking lot in Hood River. They were passing through the gorge on their way south, searching for a 17″ tube when all the dealerships were closed. Turns out that Lee had two 17″ tubes sitting in his garage: one for the tire and one for a spare. Back on the road! See you two out there in the world again sometime, somewhere.

These cool hardware bags are now included with puck kits and miscellaneous hardware shipments. What should we call this lizard? The Wrenchy Lizard?

Like Hunter Thompson said: when the going gets weird, the weird turn pro. It’s a weird time. We gotta’ stay weird to keep up.

Thanks for all your patience and support!

Warranty and Crash Replacement

We never cut corners during development or manufacturing, so we stand behind our products. If one fails due to a problem with materials or workmanship, we’ll make it right.

Your are successfully subscribed for email notifications.

Notify me when available

We will send you a notification as soon as this product is available again.

Your email is required

We don't share your email with anybody

x