Your Cart is Empty

Luggage

Apparel

Events

The Mosko Blog

Elephant in the Room

May 21, 2021

May 21, 2021

I’ll start with the elephant in the room: we are still sold out of almost everything.

We’re about 45 days from remedying that situation, although we’ll receive a small shipment by air later this week and then run out again. From the first week of July forward, things should look a lot more normal. In the history of Mosko we’ve never been sold out of so many things for so long. We don’t like disappointing riders who want our gear for upcoming trips this summer. Nor do we like having operating expenses without revenue.

This is happening because – back in 2020 – we were too conservative with our 2021 sales forecast. At that time we had modest expectations for the year ahead. Starting in February, we saw a huge spike of orders that has not let up since. We quickly used up all the inventory we’d built for Q1, plus we used up all our safety stock as well. When we saw what was happening we ramped up production, but that inventory won’t arrive until July.

The whole outdoor market is heated right now. After a year of being cooped up, everyone is back outdoors with their bicycles, motos, vans, campers, boats, tents, 4x4s, etc. Sooner or later things are bound to return to normal, at a level that’s higher than before the pandemic but lower than the peak. We don’t want to have a mountain of inventory, credit, and overhead when that happens. We scaled up a lot already to get here.

The business hustle of the last 12 months, combined with less show travel and more time to brainstorm, design, and ride, has given our product development a major boost. Ideas are flowing, and we’re awash with new prototypes and samples. Nearly everyone on the team is vaccinated, and we’re all back in the shop together for the first time in over a year. It’s a great feeling.

Lots to catch up on, and many pics to share.

Welcome Ryan, Azure, Fernando, and Bear!

We have some new team members to announce.

Ryan Turner (@eatsleepmotobeer) is joining our team as Field Sales Manager. If you visit us at a show or meetup this summer, you’re bound to meet him. Previously Ryan worked for a beer distributor in Colorado, and he recently relocated to the Northwest to join Mosko. He rides a KTM 890 and he’s about to get a KTM 300 for trail. Here’s Ryan on his first day, just seconds after walking through the door at the old shop.

Azure O’Neil is joining our team part time, working remotely from Florida, to help plan, schedule, and produce our annual event tour. Azure previously spent 5 years living off her 1989 Honda Transalp XL600V and traveling all over the world. She’s part of the core team that puts on Overland Expo. Here’s Azure on Day 1 in White Salmon, ready to dive into our show schedule with Ryan and Ash.

Fernando Eugui joined Mosko in Customer Service last week. Fernando is based in Munich, Germany, and he speaks Spanish and English fluently, plus he’s learning German. He’ll be working closely with both our US and EU sales/service teams. Previously he was Area Sales Manager at BMW in Mexico City. He rides a BMW F850GS and a Husky 250 for trails. Since Fernando’s in Germany, we did his ‘welcome’ over Zoom.

Bear (aka Tom Hoffman) started this week. His first job is to build our new showroom in White Salmon – including hosting customers when they visit – and he’ll be managing the Bates Mototel (Mosko’s free moto campground) as well. In addition to many other projects. For the last 10 years Bear has been living in Wyoming, running a snowcat at Jackson Hole Resort in the winter and spending summers in his ambulance conversion project the ‘Overlandulance.’ Bear rides an Africa Twin for touring and a KTM 530, which he’s about to swap for a NW woods bike.

Welcome aboard all!!

The Wildcat 12L & 7L Backpacks

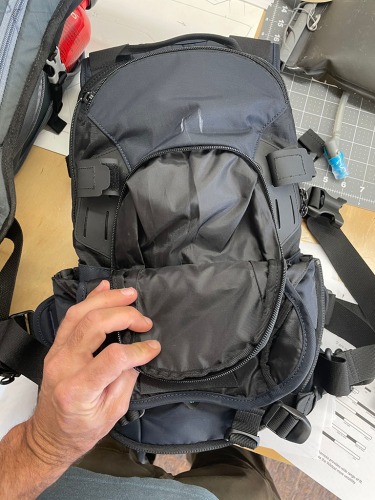

We’re so stoked on the new pack. We got a box of prototypes just before we left for the team ride in Utah, and several of us used them on that trip. Here are some pics of the 12L version. We’re actually one generation beyond this now, but these are the most thorough pics I have.

These shoulder adjustment straps have moved inside the pack itself. They’re no longer visible on the shoulder strap. Set it and forget it.

The Wildcat carries 3L of water. An internal debate we had recently, was whether to stick with the lumbar hydration reservoir or change to the standard vertical torso reservoir. After experimenting with the lumbar for several months, we decided the torso shape was better. Some of the reasons are: 1) it allows for more functional space in the main pack compartment, 2) it keeps the weight closer to your body (although higher), and 3) it opens up more pack volume as you consume water throughout the day.

This MOLLE panel can be used for things like a first aid kit, fuel bottle storage, lash points, etc.

The beavertail expands with this side zip.

Also a mesh drain panel.

These are tool holders. For a manual air pump, loppers, etc.

This pocket will have a bunch of internal organization.

There will be a small clear pocket inside of the beavertail, for an ID tag with ownership info.

The back panel will be made from compression-molded EVA foam.

The construction will be similar to this panel from another pack Andrew designed at DaKine.

It will come with a waist strap, which is easily removable with a gated clip.

The harness is extremely adjustable to fit many different size torsos, From little Ash at 5’5″ up to me at 6’3.”

The shoulder harness connects to this removable chest rig. We’ve gone back and forth on the chest rig. We all like it, but it makes the fitment challenging for folks on the outer edges of the size spectrum (large or small). It doesn’t get wider or thinner for different body types. We’re continuing with it anyway, since so many of us dig it.

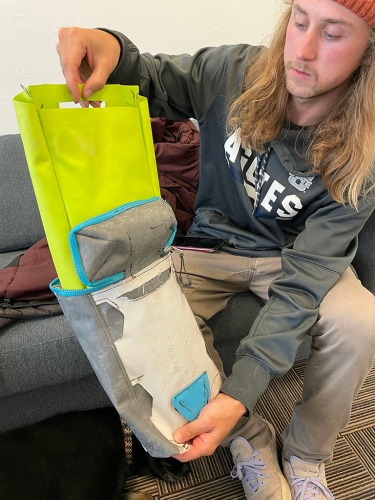

We’re also introducing a smaller version of the pack, the Wildcat 7L. It has the same shoulder harness on a more streamlined bag with less volume, fewer features, and a smaller reservoir.

These packs were a long time coming. Andrew designed many packs at DaKine, so it’s neat to see that experience in action on our own designs. I can easily see more packs, hip bags, and possibly a tactical vest as natural extensions. All of those have been requested at one time or another. Most of us have at least 3-4 different packs, hip bags, and vests for various sports in our closets, so this will be a fun (albeit crowded) category to play in.

Mosko/Rheon Body Armor

After years of frustration with body armor, we’re embracing the inevitable: it’s time to make our own. All the armor companies are so focused on track, race, and mountain bike that nobody (other than us) seems all that interested in travel and trail. Plus most body armor flows through the traditional MX supply chain superhighway, with factories selling to importers selling to distributors selling to retailers. Everyone takes a bite. The retail price of a typical roost guard, kneepad, or elbow pad has so much distribution cost built into it, that it would be hard for those companies to do anything super interesting design-wise.

We’re not tackling this solo. We’ve partnered up with a company called Rheon Labs, a relationship that emerged last year from an advrider.com connection. Rheon is a relatively new company (2017) with patents on a cutting edge new technology that we think will be the new gold standard in protective gear. Their patents cover a higher percentage of non-Newtonian liquid than D30, formed into auxetic shapes that compress in a specific way for a specific outcome (like a shoe sole). They can use less material for the same amount of protection, with better ventilation and less weight. It’s more protective, more breathable, more flexible, and a hell of a lot more comfortable than anything we’ve ever seen.

These pics are of a Rheon CE1 Type A, whereas our pads will be CE2 with more coverage. Scottie brought these samples to a team dinner at Ames’ house so we could all inspect them in person. The reaction was strong and visceral. The material itself, the auxetic shapes, the flexibility, the light weight, the huge ventilation holes: this is the armor we’ve been searching for.

We froze one of the pads and, like other non-Newtonian pads, they do get brittle and eventually snap if you bend them back and forth a few times frozen. However because of the open shape, they also warm up very fast once they’re close to your body. Like <30 seconds out of the freezer.

We’re working with Rheon to develop a chest, back, & shoulder harness combo, plus separate knee, elbow, and hip solutions. We want something vaguely similar in shape and concept to MX armor, but more protective, not as stiff, and not as hot. Something you can live in all day for weeks/months/years. It has to be tough enough for countless get offs, easy to clean, compatible with apparel layering, and we don’t want to look like gladiators.

This project is still in its infancy. Stay tuned.

New Apparel Designs

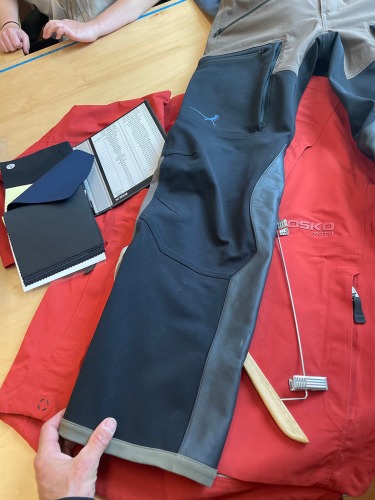

This is the first sample of a new design we’re calling the “IR” jacket and pant. IR stands for ‘Integrated/Removable’ and it refers specifically to the body armor. The idea is to make a liner-free shell jacket, with some (but not all) of the classic ADV touring features like storm flaps and top down pockets, plus an integrated version of Rheon’s badass armor technology, applied in such a way that it’s extra easy to insert or remove when you want to switch between separate & integrated armor. On hotter, mostly dirt trips, you’d run it with separate body armor so you can roll it up small and stash it on the bike. For commuting and/or cold weather pavement trips, you’d leave the integrated pads in.

First impression, first prototype: it looks amazing. I would wear this jacket. There are still a ton of details to sort out though. We’re hoping this one will be ready for 2022.

We experimented with this zig-zag tightening strap in a tunnel on the sleeve. It doesn’t really work – too much friction, too many bends – but it looks cool. It might work with a few minor edits.

A key to this jacket is the idea of laminating armor pockets to the inside of the shell, rather than suspending the pads in a loosely fitted, hanging inside liner. The armor pockets in this first sample are just for illustration, they’re not to actual size. We’re still waiting for insert prototypes from Rheon.

We’re also playing with this stuff called ‘Block Tapey’ to hold the armor pads in place, and make it possible to adjust their position. Block Tapey is like big chunky velcro strips. Funny name, cool stuff.

I have a finished-looking sample of the new Woodsman OTB (over-the-boot). Hopefully I can test it this weekend. It looks and feels great, like a finished product.

In Moab a few weeks ago, Andrew was testing a new mesh trail pant concept. This was a first round proto but he wore it for the entire week, with mostly positive feedback. I’m digging this mesh material. It feels super tough. The pants are in my hands now and I’ll be testing them as soon as it’s warm enough.

This is a prototype of a new soft shell trail jacket, sort of a ‘top half’ to go with the ‘bottom half’ Woodsman. The jacket itself looks great. Some of us are really into it, while others are questioning where it fits in their riding kit. The idea is for a warm but not too warm, non-waterproof, stretchy outer layer designed for desert and trail riding. It’s windproof, and would work great under an outer shell or as an outer layer on its own. Thoughts? We’re still moving forward, we like the jacket a lot.

Along similar lines, I’ve been digging on Scottie’s Patagonia Houdini windbreaker that has been sitting in the shop these past few weeks. It rolls up so small that you can literally stick it in your pocket. It’s not waterproof, just a wind layer. The only trouble for moto is that it wouldn’t hold up in a crash. Still, it’s only $100 retail which is a pretty good value. I just ordered one for mountain biking. Something like this but a bit tougher is something I’d love for trail. Tiny, inexpensive, ultra-packable.

Woodland: New Bag Colorway

We have a new bag colorway called ‘Woodland’ on the way. The orange colorway we introduced earlier this year was popular, and maybe we will bring it back in the future. This new colorway is a little less of a crowd pleaser, and a little more eclectic, but we love it too. We want to start messing with more nuanced colorways than what you’d normally expect from moto luggage. Most moto bags with color follow the same simple formula: swap a PVC/PU/Vinyl fabric panel to a basic color – often a motorcycle OEM color like red, blue, orange, green, or caution yellow – and/or change the color of the webbing. That’s what we did on the orange colorway and it worked out pretty well, but it wasn’t all that unique.

Now we’ll be experimenting with some more interesting outdoor and natural colors. The Woodland is actually a sort of green, with orange hits (but not caution or KTM orange). On the sewn seam bags we’re not only swapping the PU but also dying the Ballistic as well, which is something we haven’t done in the past. We don’t expect this to sell as fast as the orange, but hopefully it marks the beginning of a new direction for Mosko color wise. Is it too much of a departure from what people are used to? I guess we’ll find out.

New Tank Bags

We got new samples of the Gnome, Nomini, and Neco, as well as a new handlebar bag we’re tentatively calling the Gnat. All look great, and have been getting used a lot on our own personal bikes these past 4 weeks. These are basically ready for production.

Lee’s Knob

In Moab, a bunch of us tested a new mounting system Lee developed for the Reckless 80 (and 40 and 10) that we’re affectionately calling ‘Lee’s Knob.’ The idea is a metal knob that mounts on the bike, and a horseshoe-like connector on the harness that slides onto the knob. There’s a set screw on top to stop it from coming off, and the whole system is tensioned by the front leg straps, entirely eliminating the need for rear straps. It keeps the bag firmly in place, and makes it impossible for the harness to list to one side or the other (always an issue with rackless bags).

This is something that could be included with new R80s and retrofitted to old ones, or offered as a standalone upgrade depending on the cost. We tried it on 5 different bikes and it was crashed on and abused without a single issue. Lee is making a few more tweaks, but even as it stands right now I’m super into it. A bunch of us are also using Voile straps to replace the webbing on the legs, which is also working great and pairs well with the Knob.

I feel like our next round of improvements to the R80 should be on the mounting system more so than the bag itself. The nylon straps we currently use were a good way to get the ball rolling, and it’s great how easily they transition from one bike to another, but we all feel like there’s still an evolution yet to come, which is long overdue.

The Bates Mototel

The Bates Mototel is open! Come visit us in White Salmon!

This is our free backyard campground for moto travelers. This year we have more parking, so we’re also opening it up to friends-of-Mosko who are van, truck, and car camping. It’s a steep hill to get up there, so 4×4 is preferred although not always necessary. There’s no trailer turnaround, and not enough space for RVs although we do occasionally make an exception. If you want to stop by, contact Mosko customer service at moskomoto (at) moskomoto (dot) com.

This spring we made a number of significant improvements to the Mototel, with the help of our good friends Geoff and Reynaldo. First Geoff built this badass cedar platform for the wall tent (aka the ‘Dusty Lizard Lounge’).

Then Reynaldo built an outdoor kitchen and shower, also from cedar.

The end result looks awesome. Nice work and THANK YOU Geoff and Rey. You guys are the coolest.

The first early season crew came through while I was in Utah. Sorry to miss you guys!

If you want a Mototel sticker, you gotta’ come and get it. There’s a stack on the bar in the tent.

If that layout looks familiar, it’s from this:

Mosko’s New-To-Us HQ

Back in January, Mosko acquired a new HQ in downtown White Salmon. Since then our buddy Steve has been inside with his construction crew clearing out old walls, painting, and getting it move-in ready. The building was last improved in 2009 and it was vacant for over a year, so it needed some love.

Here’s what it looks like now. This is the upstairs. There’s a downstairs too, which is where the CS team lives and where the new showroom will eventually be. We’re still moving in, hanging pictures, etc. This building will be a long term project.

It’s exciting to have a permanent home, for the first time in the 8 years since we started Mosko. We came back from Moab fully vaccinated, moved into the new building, and all moved back into the office after more than a year of mostly working from home. Plus the mask requirement was lifted, and we can hug and shake again. It’s a great feeling. Like before but better, because we’d missed it so much.

The building was built in the 1920s and it has at various times been a bar, restaurant, and aerospace company. At one point it was even a Safeway.

Other Stuff

Here’s a collection of some other stuff from the last few months.

New box stamps.

Here’s a useful way to rig stuff like fuel bottles or a camp chair on a Reckless 80 harness. Maybe we can build this into the bag somehow, like with a passthrough for Voile straps.

We’re getting back on the road no holds barred, starting in July. We’ll be at every sizable event that’ll have us, including all the IMS shows, BMW Rally, KTM Rally, Overland Expo, and a ton of meetups. Ash, Ryan, Azure, JC, and I are ready to roll. Our first meetup – kind of a shakedown run – is June 9th at the famous See See Motorcycles in Portland. Stoked for that!

With so much new product to display, we’re also redesigning the booth. We’re adding a 40′ awning to the show trailer, so the trailer will now be part of the display, and it’ll also be a changing (and break/nap) room.

JC built a sick new tilt trailer (starting with an old steel deckover flatbed from craigslist) to haul the you know what(s) to that thing and that other thing in the desert.

Most of us did this.

This was sitting on my laptop one morning. It’s a banana protector. For camping. Turns out everyone at Mosko got one. Unfortunately our bananas don’t fit inside very well, but it’s the thought that counts.

Our buddy Enrique got one of these sick Sur-Ron electric bikes. Man these things are fun to ride. It’s neat to see a new category. It’s not an e-bike but not an electric dirt bike either. It’s something new. Don’t you just want one? Man, I do.

Jesse Robinson – formerly ‘Jesse the Intern’ and now ‘Jesse the Design School Graduate and Freelance Designer Who Lives a Block Away From HQ’ – is working on an update to the large MOLLE pouch. He has some cool ideas.

Roel’s new van wrap!

Time to choose some colors! The person on the right side of the table with Dave, is Brittany Crook. She’s a freelance designer based in Canada, who worked with Andrew and Scottie at DaKine, and before that at ArcTeryx. She’s the mastermind behind the soon-to-be IR jacket. She rides too.

In Sweden: R80s for snow travel!

Azure, traveling on her way out to meet us in Grand Junction, CO for the team ride, stopped to attend a wedding. In her moto boots.

Beans. Lots of beans. This is how we measure the volume of a bag.

New box inserts arrived.

Mosko Spring 2021 Team Ride

Here are some pics from the Mosko team ride. To Moab and beyond. It was a blast. Except for Lee breaking his leg (again) and Forest tearing his ACL/MCL (also again). We had 17 people on the ride, so a few crashes were inevitable, but all of us really feel for the two guys reliving past injuries. That could’ve been any of us: you took one for the team. We owe you. Heal up fast!

Also, here are some shout-outs to people who really made this trip special.

- Our friends Alex, Penny, John, Barak, Michael, Jeff, & Crew at Motodiscovery Tours & Training in Grand Junction, CO. They provided training for those who wanted it, a guide for the ‘green trail’ group, and backup support for the entire trip. Including evacuating Lee when he broke his leg. You guys are the best!!

- My buddy Mike aka ‘Taco Mike’ from Taco Moto in Las Vegas who, when my bike started acting up just days before the trip, said ‘stop by Las Vegas on the way to Utah and I’ll take the engine out of my bike and put it in yours.’ And then he did just that, so I had a bike to ride. That’s a friend indeed.

- Our new friend Eric Waterfall from Ruby Moto lighting in Ogden, for surprising us at our campsite near Moab with his converted school bus overland vehicle, and coolers full of drinks, food, and cooking supplies for 17. No freeze dried backpacking meals were eaten at that camp. We are getting soft.

- Our new friends Scott & Julie at 3 Step Hideaway, a super cool stopover on any Utah ADV trip. What an epic spot and great people. The woodfire hot tub, the dinner and breakfast, the killer location, the friendly owners, and sleeping in a teepee were memorable.

- Cheers to our buddy Ned Suesse from Doubletake Mirror for rolling in with coolers full of beer, for the wheelie demonstrations and advice on White Rim trail, and for being such an epic dude and big personality.

It’s hard to find people you travel with well, especially a whole company full of people you also happen to work with. The experience of building Mosko has been like one long awesome moto ride in some wild place. I’m happy the team trips are still so fun and organic despite the larger size. Everyone splits up, most of us navigate for ourselves, and everyone rides their own ride at their own pace. Somehow we all meetup at night (usually). Minimal logistics, minimal drama. Love this crew.

Warranty and Crash Replacement

We never cut corners during development or manufacturing, so we stand behind our products. If one fails due to a problem with materials or workmanship, we’ll make it right.

Your are successfully subscribed for email notifications.

Notify me when available

We will send you a notification as soon as this product is available again.

Your email is required

We don't share your email with anybody

x